2022 High quality Eyelet Ring Machine - Automatic Punching & Eyeleting & Riveting Machine (Pneumatic) JZ-989GPQ – Jiuzhou

2022 High quality Eyelet Ring Machine - Automatic Punching & Eyeleting & Riveting Machine (Pneumatic) JZ-989GPQ – Jiuzhou Detail:

Application

Suitable for automatically setting eyelets, grommets & necked washer on canvas, tarpaulin advertising banners, garments, shoes, belts, handbags, paper bags and hats, leather products, bags and suitcases, etc.

Feature

1. Pneumatic machine, stable performance, low noise.

2. Automatic feeding of both eyelets & necked washer, solve the speed of manual feeding and improve the production efficiency. make the operator avoid injure, more safety.

3. It’s can be punching & fixing eyelet at the same machine. Hole pre-punching is not necessary.

4. It’s setting 2400-3600pcs in one hour, with high efficiency.

5. Adopting infrared indicator light, precise positioning, time-saving and labor-saving.

6. With touch computer display control panel, it is more convenient to manage operation, parameter setting and functional selection.

7. With CE certificate, product quality and safety are more guaranteed.

8. Different sample effect with different die set, there have cutting die, flange die, flower die for customer choose. with good eyeleting effect.

9. It’s simple to operate and simple in structure, which is more convenient for maintenance.

10. One year warranty, expect human factors and wearing parts.

11. Different voltage applicable to different countries, different regions: 220V single phase,380v three phase,110v single phase…etc.

12. The feeding accessories are produced and customized completely according to the position of the product, eyelet size, and adjust it according to the thickness of the material, only needs to connect the power supply then can use it directly.

13. Provide a good after-sales service system to solve various problems encountered by customers during use.

14. A wide range of applications, for different products, different specifications, different materials, different shapes of metal grommet riveting, can be accept special customized.

Application

Our Service

Product detail pictures:

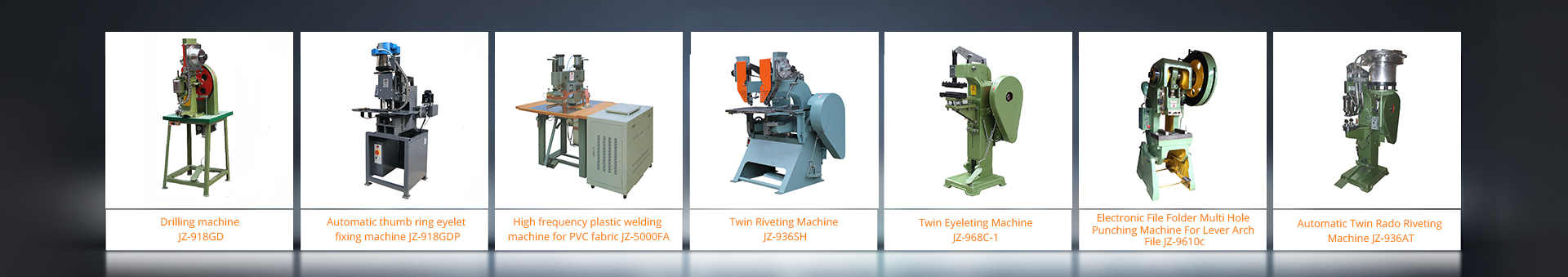

Related Product Guide:

go on to boost, to be certain item quality in line with market and buyer standard demands. Our firm has a excellent assurance procedure happen to be established for 2022 High quality Eyelet Ring Machine - Automatic Punching & Eyeleting & Riveting Machine (Pneumatic) JZ-989GPQ – Jiuzhou , The product will supply to all over the world, such as: Switzerland, Denmark, Seychelles, Many years of work experience, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.