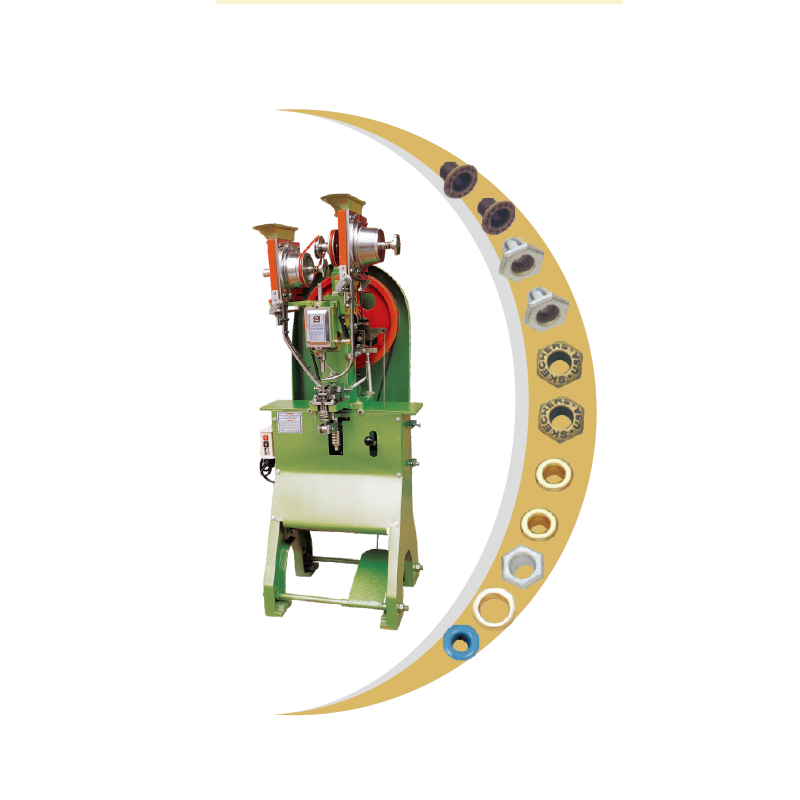

Best quality Pneumatic Riveting Machine - Pneumatic Automatic Twin Rado Punching and Riveting Machine for Lever Arch File / File Folder JZ-936ATP – Jiuzhou

Best quality Pneumatic Riveting Machine - Pneumatic Automatic Twin Rado Punching and Riveting Machine for Lever Arch File / File Folder JZ-936ATP – Jiuzhou Detail:

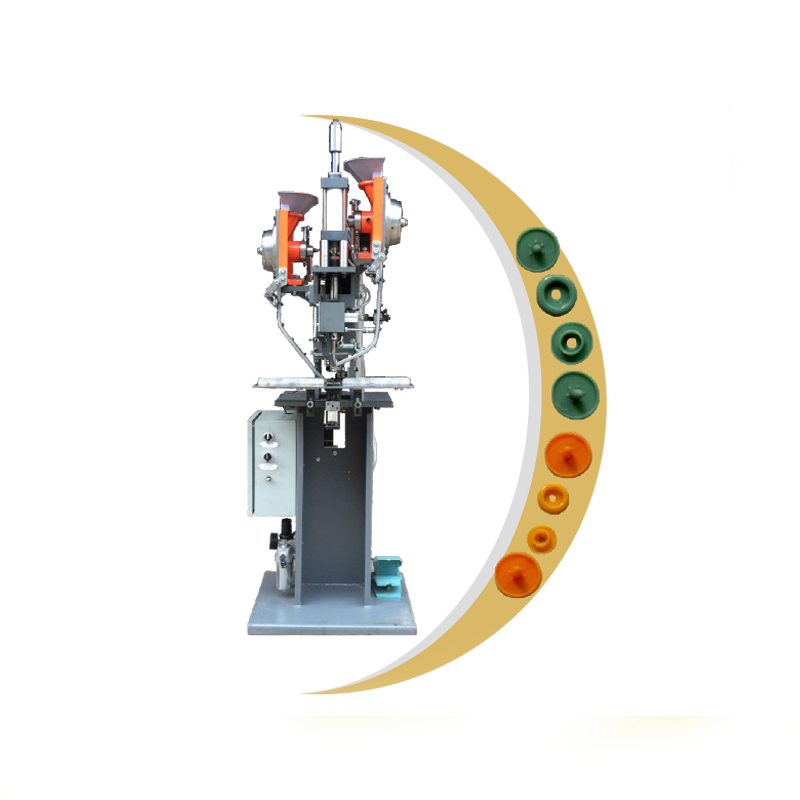

Application

This machine is designed for simultaneously setting of 2 rado eyelets on lever arch files, file folders.

Feature

1. The standard head distance is 80mm, high accuracy. And the customized distance is available on request.

2. Two oval eyelets are automatic feeding and setting at the same time, increase productivity,avoid work-related injuries.

3. Big vibrating tray bowl feeding, vibration speed and discharge speed all are adjustable.

4. Dual track simultaneous feeding output, and the machine has punched 2 waist-shaped holes at the same time.

5. Foot switch and travel switch operate at the same time, safer operation.

6. Precise positioning: position can be adjusted in all directions: front, back, left and right, the tightness of the riveting…etc.

7. Double servo motor drive, pneumatic type, safer to use and stable to operate with low noise.

8. With touch screen, debugging and maintenance of the machine is more convenient and fastest.

9. Pressure speed adjustable: punching and riveting speed and can be adjusted according to customer product requirements.

10. It’s very convenient at the automatic punching and riveting. No need to buy additional machines for punching separately.

11. Long throat depth and long stroke, suitable for different sizes of file folder.

12. Precise positioning, stable performance and good eyeleting effect. improve production efficiency of the preferred equipment.

13. High production efficiency with eyelet fastening of 2400 times per hour.

14. Die replacement is very simple, with 2 punching dies and 2 riveting dies for easy maintenance.

15. Adopt PLC control, which is easy to operate and easy to maintain.

16. Machine with one year warranty, except human factors and wearing parts, long-term maintenance.

Application

Our Service

Product detail pictures:

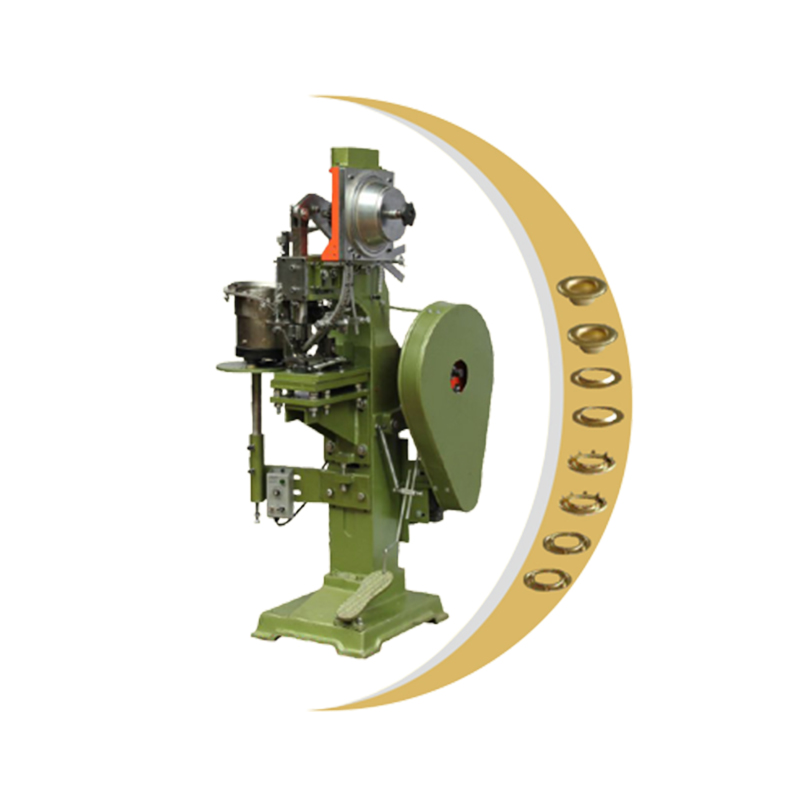

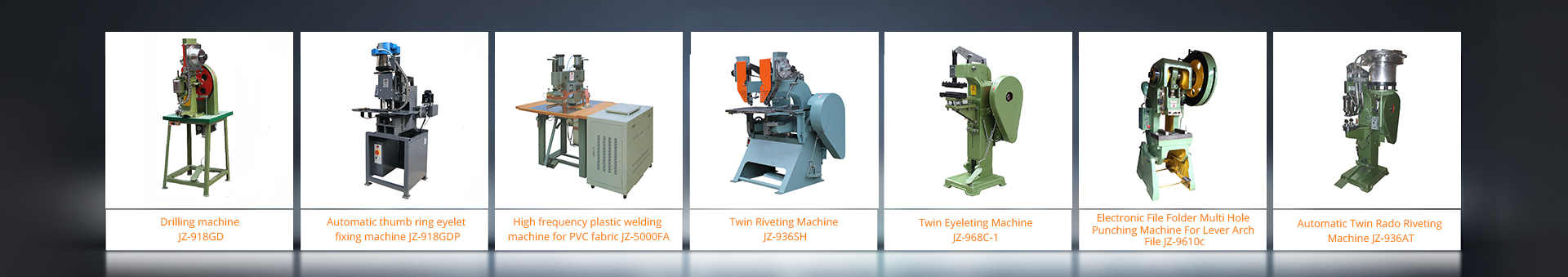

Related Product Guide:

Our crew through skilled training. Skilled skilled knowledge, strong sense of company, to meet the company wants of customers for Best quality Pneumatic Riveting Machine - Pneumatic Automatic Twin Rado Punching and Riveting Machine for Lever Arch File / File Folder JZ-936ATP – Jiuzhou , The product will supply to all over the world, such as: Germany, Cyprus, Bolivia, When you are keen on any of our items following you view our product list, please feel free to make contact with us for inquiries. You'll be able to send us emails and get in touch with us for consultation and we shall respond to you as soon as we are able to. If it's convenient, you could find out our address in our web site and come to our enterprise. or additional information of our items by yourself. We're generally ready to build lengthy and steady co-operation relations with any possible shoppers within the associated fields.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.