Chinese Professional 15mm Snap Button Machine - Automatic Plastic / Prong Snap Button Fastening Machine JZ-989N2 – Jiuzhou

Chinese Professional 15mm Snap Button Machine - Automatic Plastic / Prong Snap Button Fastening Machine JZ-989N2 – Jiuzhou Detail:

| Model | JZ-989N2 |

| Snap button head diameter | 6-20mm |

| Snap button diameter | 3-5mm |

| Snap Button length | 3-8mm |

| Throat depth | 130mm |

| Power | 0.37kw |

| Machine size | 590*550*1400mm3 |

| Net weight/ Gross weight | 120KG / 160KG |

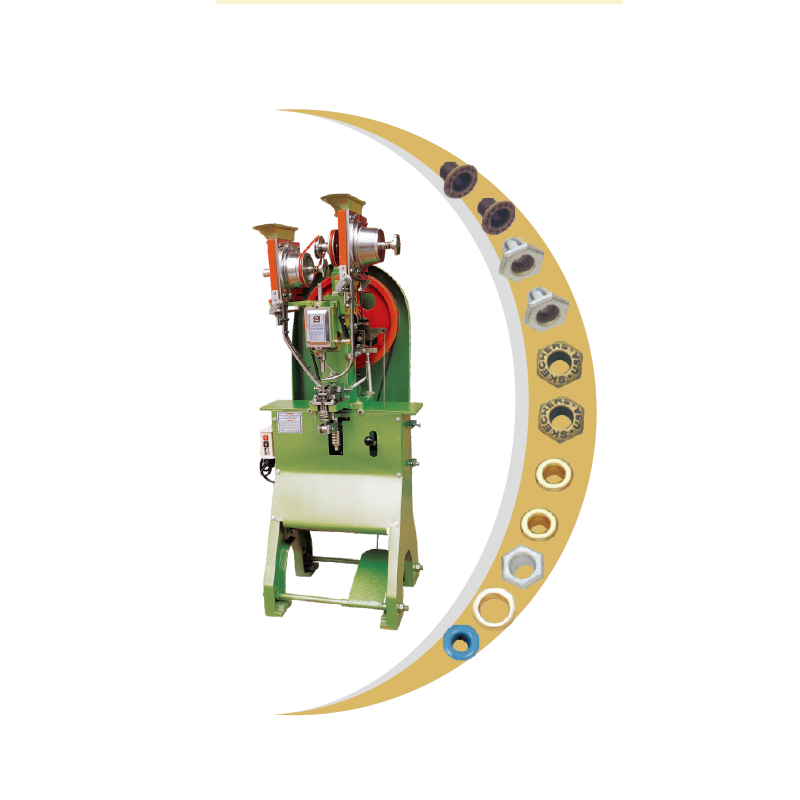

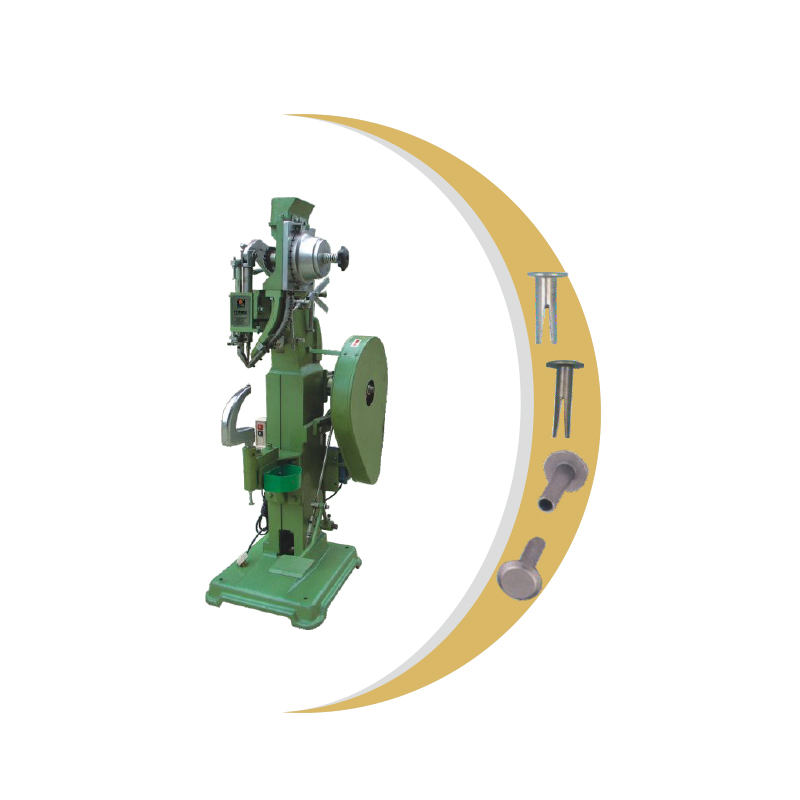

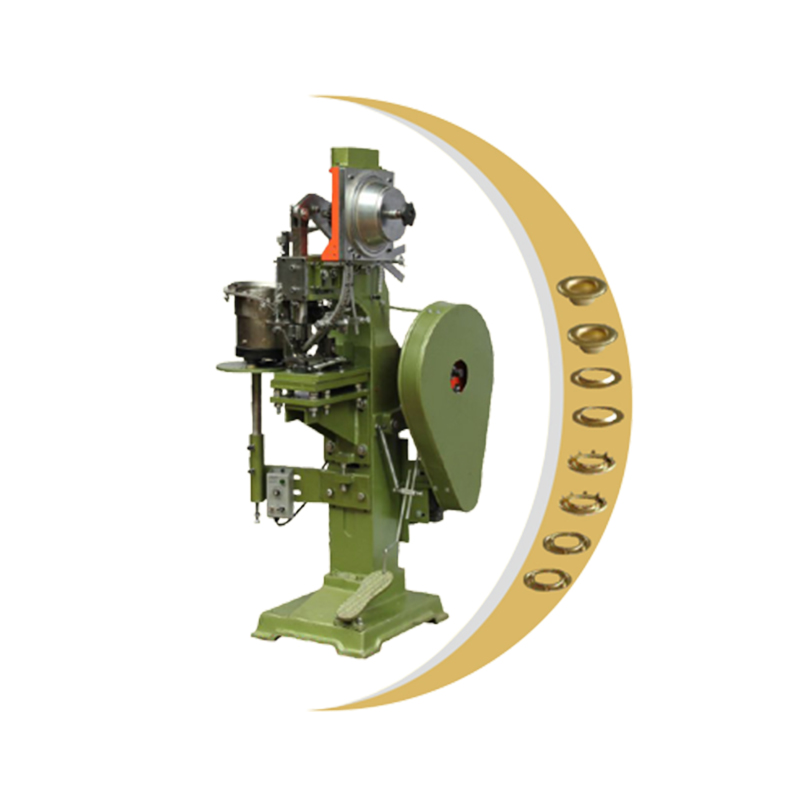

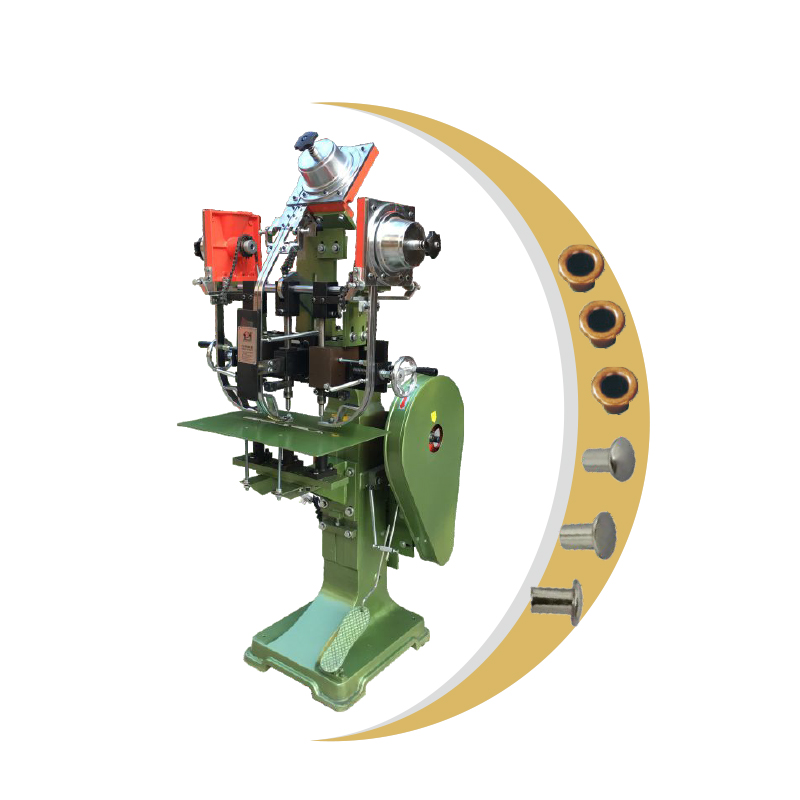

Application

This machine is suited for fixing plastic or prong snap buttons on umbrellas, raincoats, Environmental protection bags, PVC plastic bags, saliva cloth, triangles, bibs, children’s climbing clothes, and other clothing items and webbing, etc.

Feature

1.Automatic feeding cap & female / male snap parts, different with previous manual feed by hands.

2.Simple operation, stable performance without manual feed, no injury, more safety;

3.Adopt mechanical power, riveting frequency is up to 80 – 120 times per minute that is 4-6 times of manual operation. High working efficiency;

4.High compatibility: different sizes of snap button can be used on the same machine, by simply replacing the automatic feeding system & die set.

5.Machine with Servo Motor, Low noise;

6.Suitable for power supply in different regions & nations.

7.Adopt touch screen and PLC control to detect fault and display automatically; it’s easy to operate and maintain.

8.Select frequency conversion and electric energy braking system that has low noise during operation, no obvious mechanical impact, simple and durable structure and is energy saving;

9.It has laser positioning and counting function which makes fixing more accurate and statistics easier;

10.Can adjust the operation speed according to operator speed;

11.Good fastening effect: the sample effect is neat, firm, beautiful and not deformed.

12.Simple operation: After receiving the machine, remove the outer packaging, connect the power, hit pedal, then it can start to work.

13.The machine can save energy, and is an environmental protection machine.

14.Widely applications: It is widely used in packaging, clothing, bags, medical, maternal and children suppliers, daily necessities home textiles, printing and other industries;

15. Machine is small for easy handling and movement.

Product detail pictures:

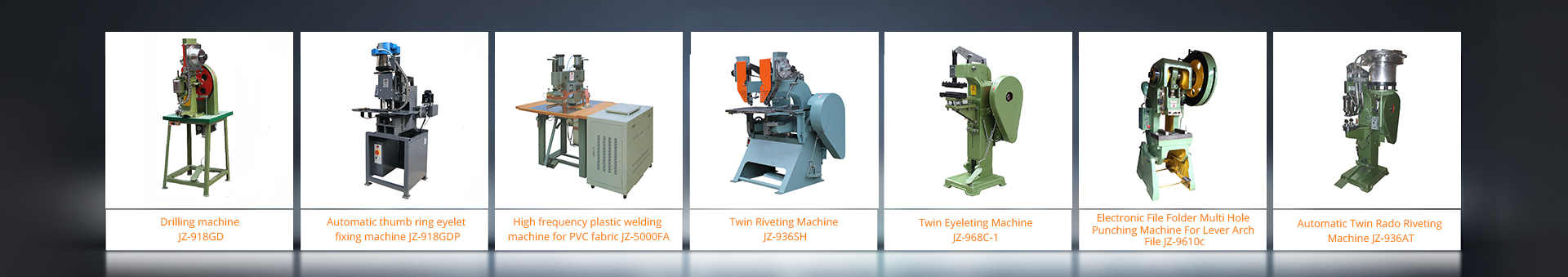

Related Product Guide:

It can be a great way to enhance our solutions and service. Our mission would be to build inventive products to consumers with a superior working experience for Chinese Professional 15mm Snap Button Machine - Automatic Plastic / Prong Snap Button Fastening Machine JZ-989N2 – Jiuzhou , The product will supply to all over the world, such as: Bangladesh, Haiti, United Arab Emirates, We welcome customers from all over the world come to discuss business. We supply high quality solutions, reasonable prices and good services. We hope to sincerely build business relationships with customers from at home and abroad, jointly striving for a resplendent tomorrow.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.