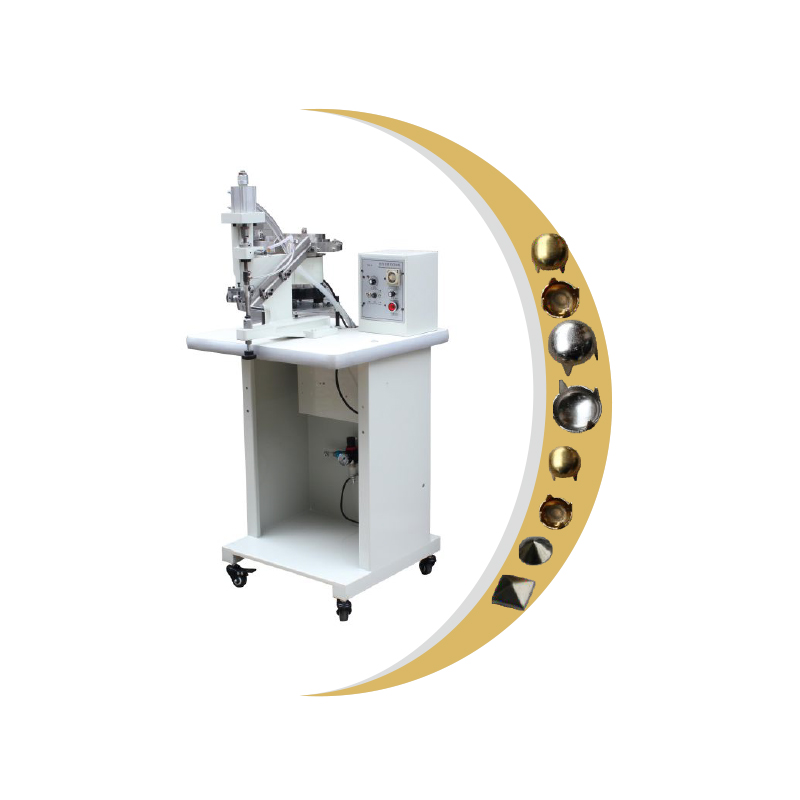

Fully Automatic Punching Machine for Spring Prong Snap Stud / Socket Part Making

Application

Automatic punching machine is suitable for continuous stamping iron sheet, copper sheet, aluminum sheet, stainless steel and other pieces of material, the machine with automatic manipulator, automatic feeder, emergency braking system, crankshaft, connecting rod and push ruler and other parts are used for bearing rotation, to ensure stable and reliable operation. It can be widely used in hardware products, metal buttons, auto parts, electrical plug-ins and other manufacturing industries.

Feature

1.Punching machine consists of auto-roll feeder, auto-feed cradle, and scrap roller. It is easy to operate and it runs fast, also it is automatic from feeding material to rolling scrap.

2.Progressive mold is made on request. Tungsten carbide is used to make parts of molds the mold is resistant to wear and tear.

3.Auto feed cradle has two parts-main body machines go more smoothly and faster;High speed metal button production line for making spring prong stud, Spring prong socket,prong snap button, jeans buttons, rivets, sewing buttons, hollow rivet, eyelet / grommet, single cap rivet, baby buttons making;

4.High strength steel welded body, tempering treatment, high rigidity, accuracy and stability.

5.Transmission parts: the gear adopts closed transmission, and through precise grinding disposal, dip oil smooth, transmission balance, low noise, long life.

6.The meshing surfaces and conflict pairs in the moving parts are specially treated with intermediate frequency, surface hardening, nitriding, etc., extending and guaranteeing the service life of the machine tools.

7.Dry pneumatic conflict brake is selected, the layout, conflict plate protection replacement convenience, easy to repair.

8.With high efficiency, low noise, longevity and other significant characteristics.