Hot Sale for Hook Machine - Automatic Hook Button Fastening Machine for Safety Shoes JZ-989HN2-1 – Jiuzhou

Hot Sale for Hook Machine - Automatic Hook Button Fastening Machine for Safety Shoes JZ-989HN2-1 – Jiuzhou Detail:

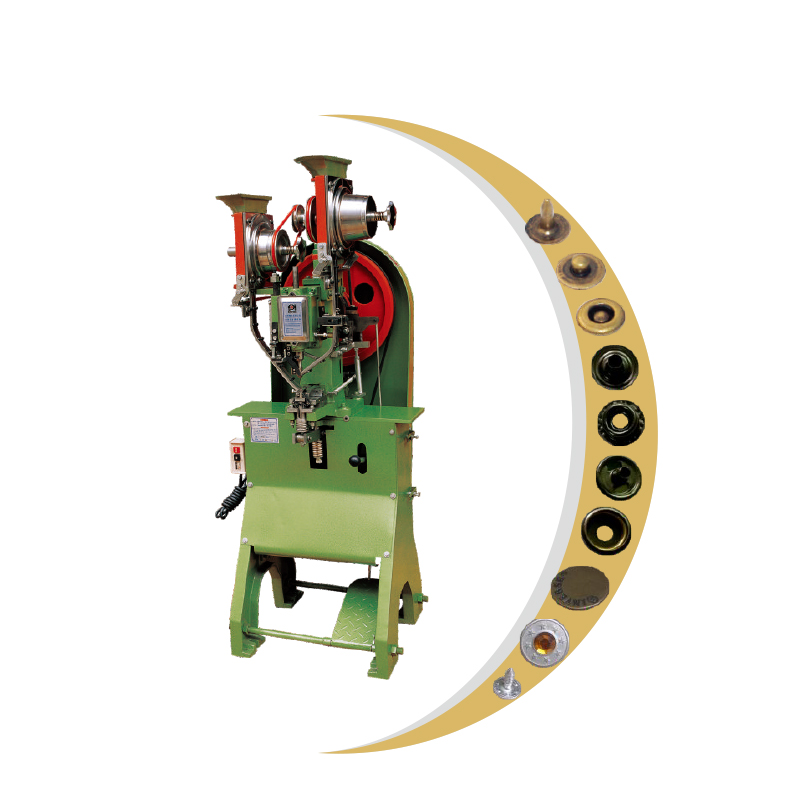

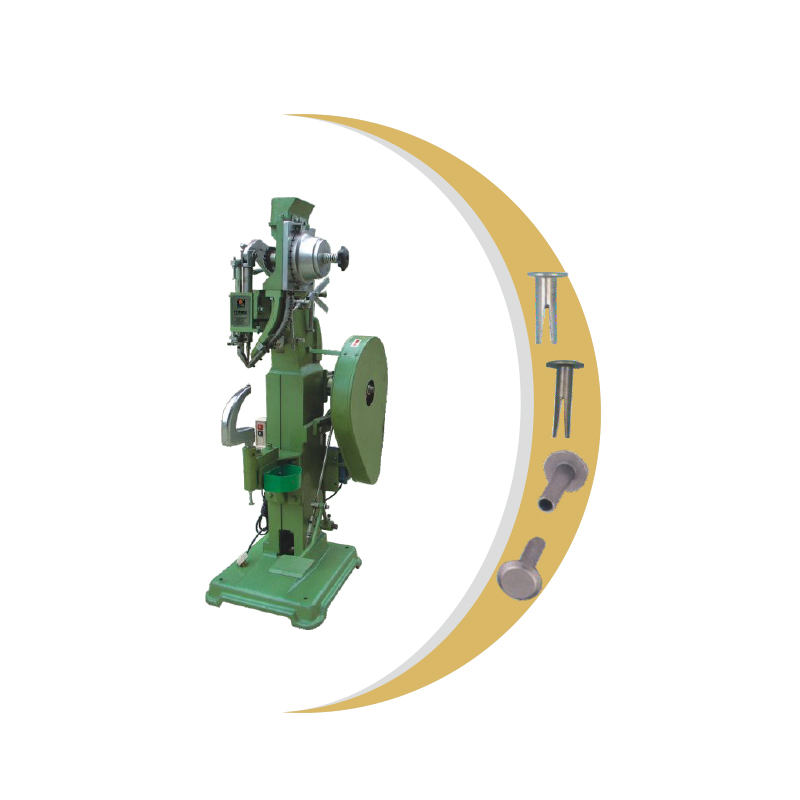

Application

Used for fixing hooks, D-rings and special buckles on safety shoes, mountaineering shoes, gym shoes and labor insurance shoes, leisure/ casual shoes, hiking shoes etc.

Feature

1. Worker no need to manual feed the hooks and D-rings by hands, ensure safety does not hurt the hand.

2. Machine automatic feeding both hook, D-ring, special buckle with lower washer, with higher efficiency.

3. Vibrating tray bowl feeding, and the advantage of vibrating bowl feeding is the neat arrangement of special buckles with irregular shapes, and not easy to scratch the surface coating of the hook button.

4. Punching & fastening the hook & lower washer at the same time, It is very convenient at the automatic punching and riveting hole pre-punching is not necessary.

5. The controller can adjust the feeding speed of the vibrating bowl, which is more convenient for customers to use.

6. High production efficiency with hook button fixing of 2500 times per hour.

7. The different shapes of lower die bases can be designed, suitable for riveting of shoe uppers of different shapes.

8. Operation with touch display, it’s can detect fault and display automatically. it is more convenient to manage operation, parameter setting and functional selection.

9. With CE certificate, product quality and safety are more guaranteed.

10. The fixing position of materials is provided with laser bright spot contrast localization, which is accurate and convenient.

11. With servo motor, can adjust speed, low noise.

12. Adopt PLC control, which is easy to operate and easy to maintain.

13. The feeding system produced according to customer’s hooks & washer, adjust very well according to the products material, once received machine only need to connect the voltage then can use it directly.

Application

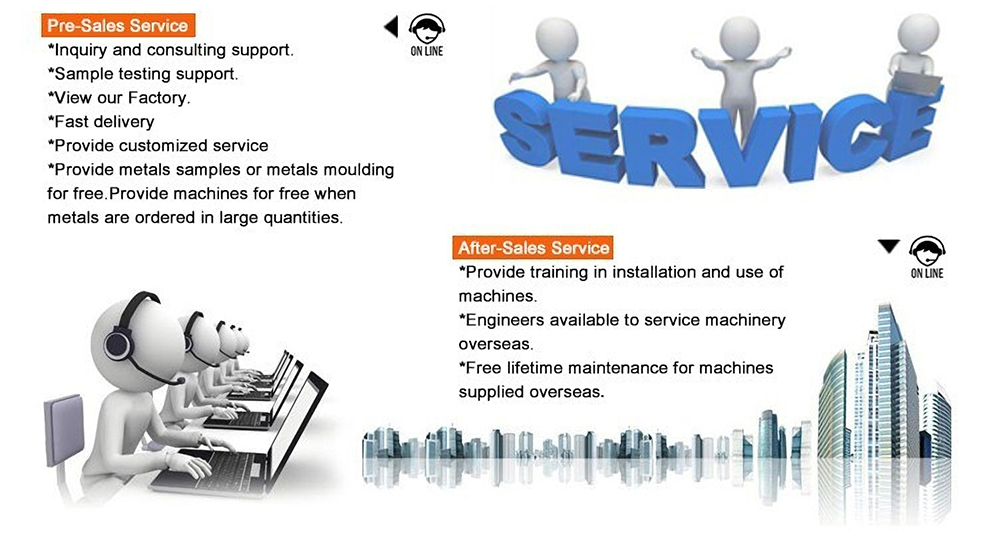

Our Service

Product detail pictures:

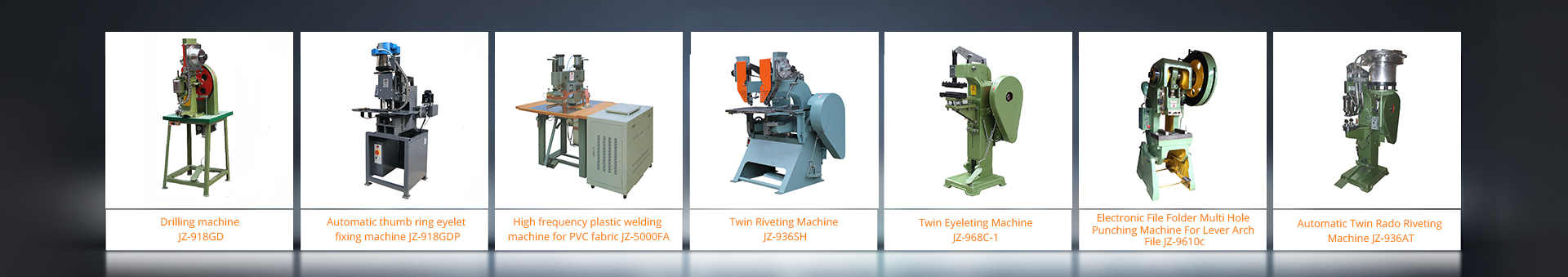

Related Product Guide:

Being supported by an highly developed and skilled IT group, we could offer you technical support on pre-sales & after-sales support for Hot Sale for Hook Machine - Automatic Hook Button Fastening Machine for Safety Shoes JZ-989HN2-1 – Jiuzhou , The product will supply to all over the world, such as: Slovakia, Liverpool, Germany, Our monthly output is more than 5000pcs. We have set up a strict quality control system. Please feel free to contact us for further information. We hope that we can establish long-term business relationships with you and carry out business on a mutually beneficial basis. We are and will be always trying our best to serve you.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.