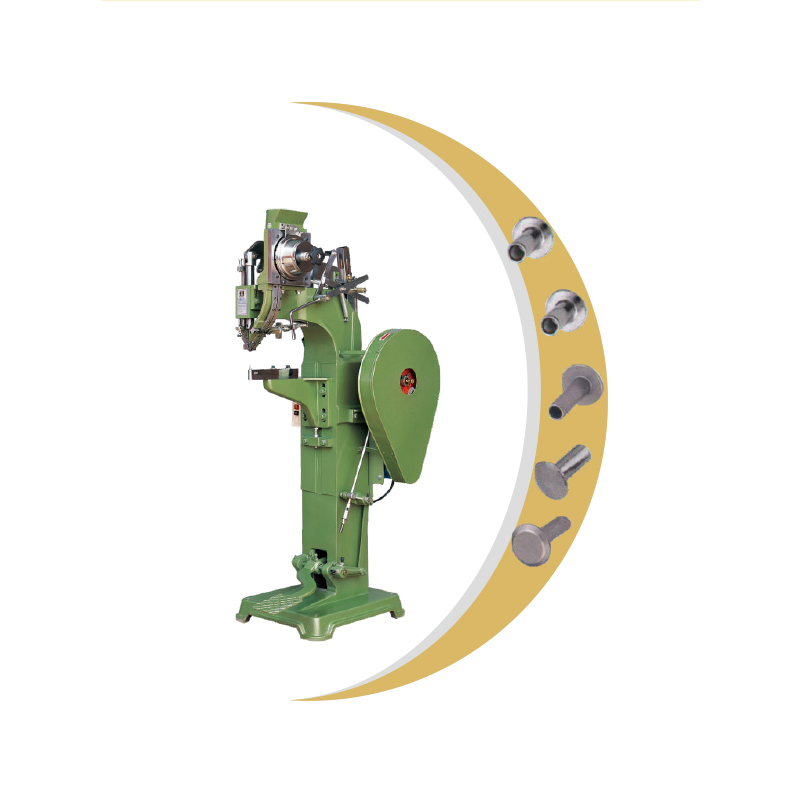

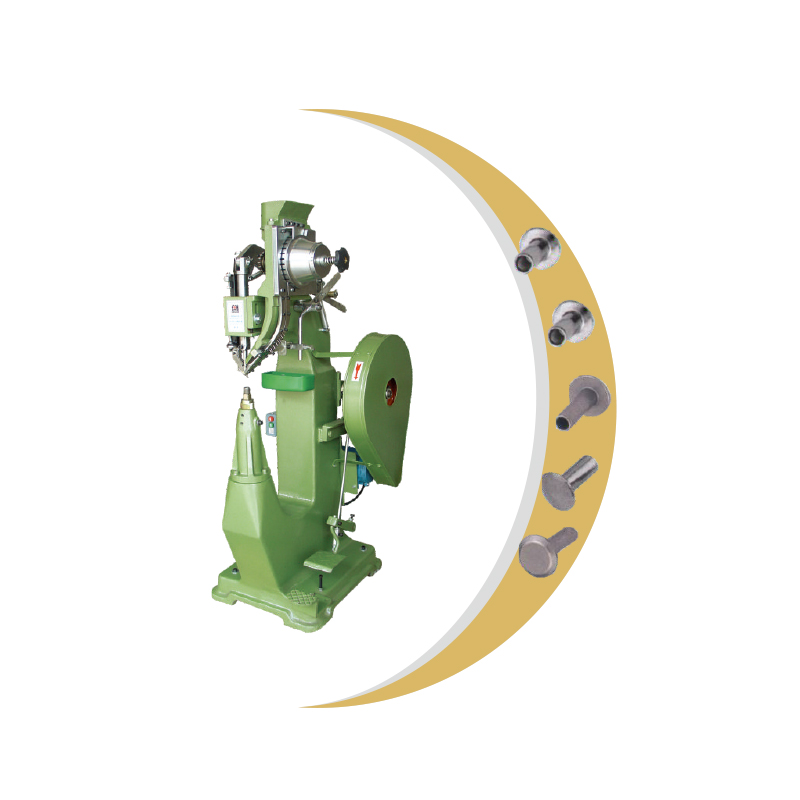

Hot Selling for Fabric Punching Eyelet Machine - Twin Eyeleting Machine JZ-968G2 – Jiuzhou

Hot Selling for Fabric Punching Eyelet Machine - Twin Eyeleting Machine JZ-968G2 – Jiuzhou Detail:

| Model | JZ-968G2 | JZ-968M2 |

| Eyelet flange diameter | O6-28mm | 6-15mm |

| Eyelet barrel diameter | (P3-12mm | 3-5mm |

| Eyelet length | 3-8mm | 3-8mm |

| Throat depth | 250mm | 250mm |

| Power | 3/4HP | 3/4HP |

| Machine size(L*W*H) | 720x660x1600mm3 | 720*660*1600mm3 |

| Net weight | 260kg | 260KG |

| Gross weight | 330 kg | 330KG |

Application

Specially used for fixing two eyelets / hollow rivets on packing box, stationery box, lever arch file, file folder briefcases, clipboards…etc. This machine adopts double-head work at the same time, is able to rivet two eyelets at the same time, and can adjust the distance according to product demand. It’s mainly used for paper bags, packaging boxes and other industries.

Feature

Suitable for fixing two rivets at the same time on packing box, stationery box, Notebook.

1.The machine can automatically punch or continuously punch and rivet eyelets, the punching and eyeleting can be finished once;

2.Can adjust the pitch of two eyelets freely according to the requirement, adjustable distance between two eyelets (7-15cm);

3. Available for continuous eyelets feeding;

4.Easy operation, automatic feeding eyelets, puncture and bending edge all finished in one move;

5.After binding, eyelets edge is smooth and good looking; locking strength is strong, not easy to tear out;

6. This eyeleting machine use electric power in place of labor power. To save the operator work force and improve working efficiency greatly;

7. High production efficiency with riveting of 40-60 times in one minute;

8. Fast and reliable operation;

9. A cast iron worktable, which ensures high stability during operation;

10. More accurate setting process compared with manual riveting machines;

11. Adopt a turntable for dividing materials. Rail conveying automatic feeding;

Specification

Model: JZ-968G2

Eyelet flange diameter:6-28mm

Eyelet barrel diameter:3-12mm

Eyelet length:3-8mm

Throat depth:250mm

Power: 3/4HP

Machine size: 720*660*1600mm3

Net weight/ Gross weight: 260KG / 330KG

Our Service

Product detail pictures:

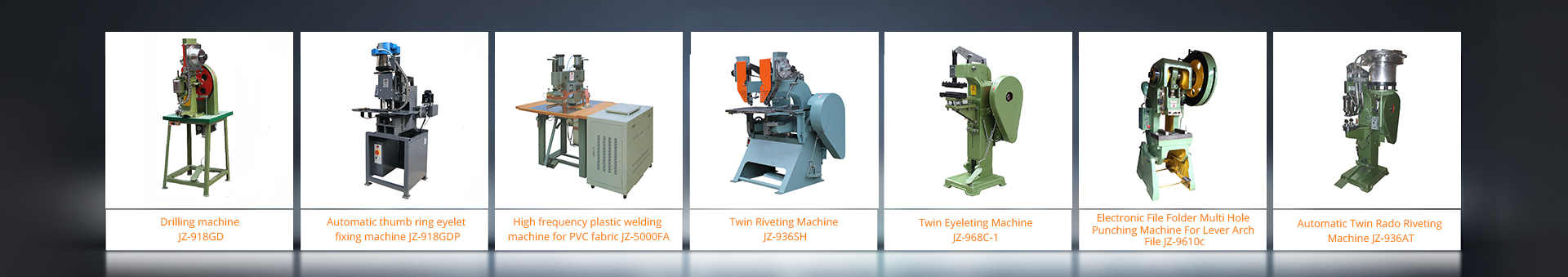

Related Product Guide:

Our well-equipped facilities and exceptional good quality manage throughout all stages of production enables us to guarantee total shopper satisfaction for Hot Selling for Fabric Punching Eyelet Machine - Twin Eyeleting Machine JZ-968G2 – Jiuzhou , The product will supply to all over the world, such as: Nigeria, Surabaya, Nairobi, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products for our customers.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!