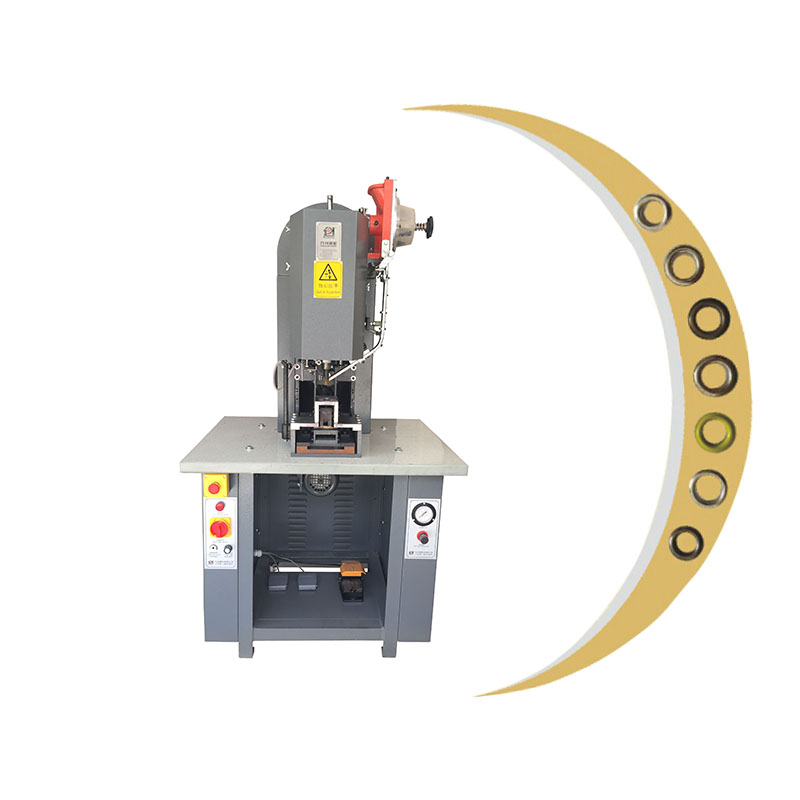

JZ-989ATP Automatic Oval Eyelet Punching and Riveting Machine for Shoe / Leather Belt

Application

Used for fixing oval eyelet on clothing, shoe, leather goods, printing, advertising…etc.

Feature

Features:

1. Newly upgraded to PLC control system, touch screen setting, adjustment is easier to understand, quicker, and automatic counting function;

2. Upgraded to servo system control, oval eyelet & flat washer are automatic feed by vibrating tray bowl, feeding speed faster, more stable;

3. Punching and riveting are completed at one time, saving punching time and improving working efficiency;

4. The laser light is illuminated vertically to ensure the accurate position of eyelet riveting,to avoid the tediousness of adjusting the laser light due to changes in the thickness of the material;

5. Equipped with a sensor device, no eyelet will not be empty playing, convenient and simple, high work efficiency;

6. Replacing the original manual feed machinery, reflecting the higher progress of the machinery industry and improve the level of technology;

7. Increase the waste hopper, to avoid the waste material scattered to the ground, thus reducing the pollution of the production environment, green and environmentally friendly.

Application

Our Service