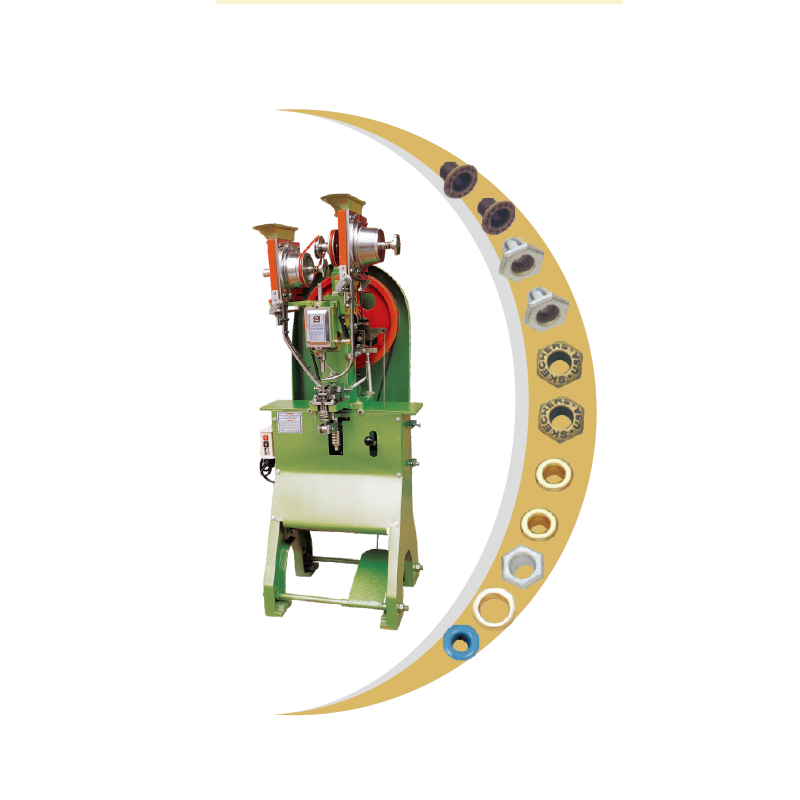

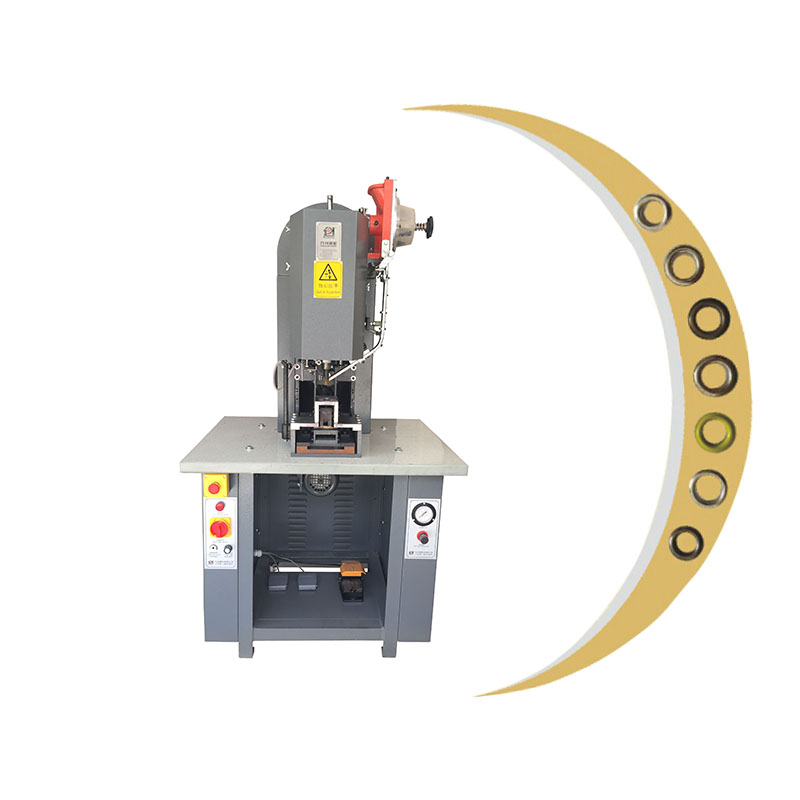

JZ-989NSP Servo Motor Automatic Punching & Eyeleting Machine for Mesh Grommet

Application

This machine is mainly applied to the work of riveting of shoe eyelet, hexagonal grommet, Rado eyelet, snap button, small and medium-sized eyelet for garments, bags, handbags, leather goods, belts, footwear, handicrafts, etc. It can be used for punching and riveting of fabrics, natural leather, PVC, PU and other materials.

Feature

The machine adopts the combination of pneumatic and electric work, the performance is as follows.

1. It adopts PLC and touch screen control, detects faults and displays them automatically, which is convenient for maintenance and easy to operate.

2. Simple structure, durability, energy saving and power saving, reduce maintenance cost.

3. Provide a variety of modes of single and continuous hitting: single mode (step on the foot pedal to hit the hole riveted only once);

Continuous mode (adjustable speed, suitable for skilled operation, improve productivity).

4. The upper and lower part use vibrating tray bowl feeding, which is widely applicable and convenient for flow eyelets.

5. The upper and lower eyelet increase the blowing function, and the eyelet are fed in automatically for higher stability.

6. Send eyelet riveting up to 50-60 times per minute.

7. Adopt laser light and red dot positioning to make the riveting position reliable.

8. The appearance after riveting is meticulous, beautiful, neat, firm, and not deformed.

Application

Our Service