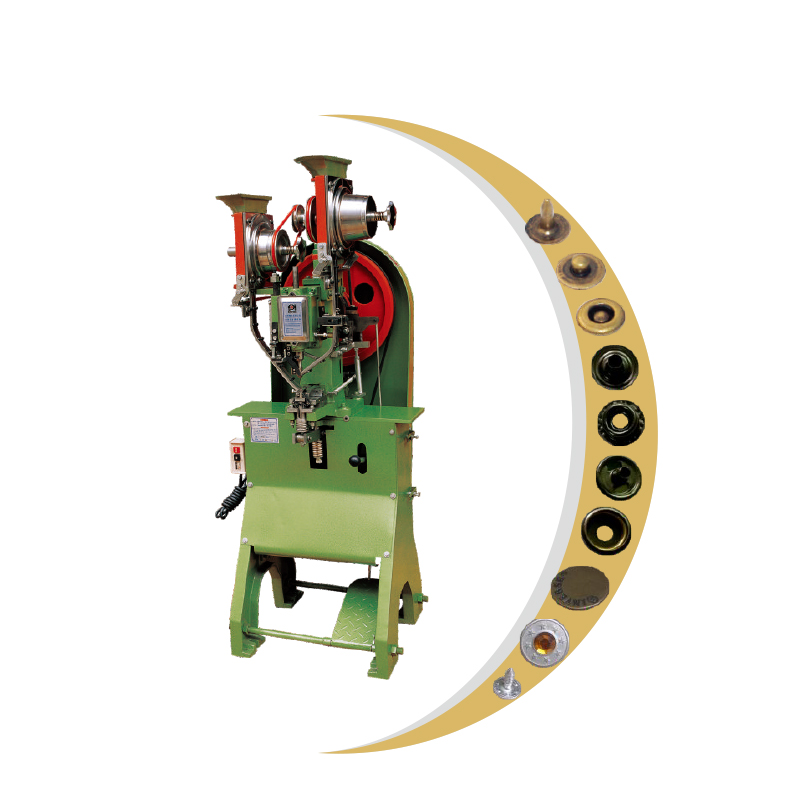

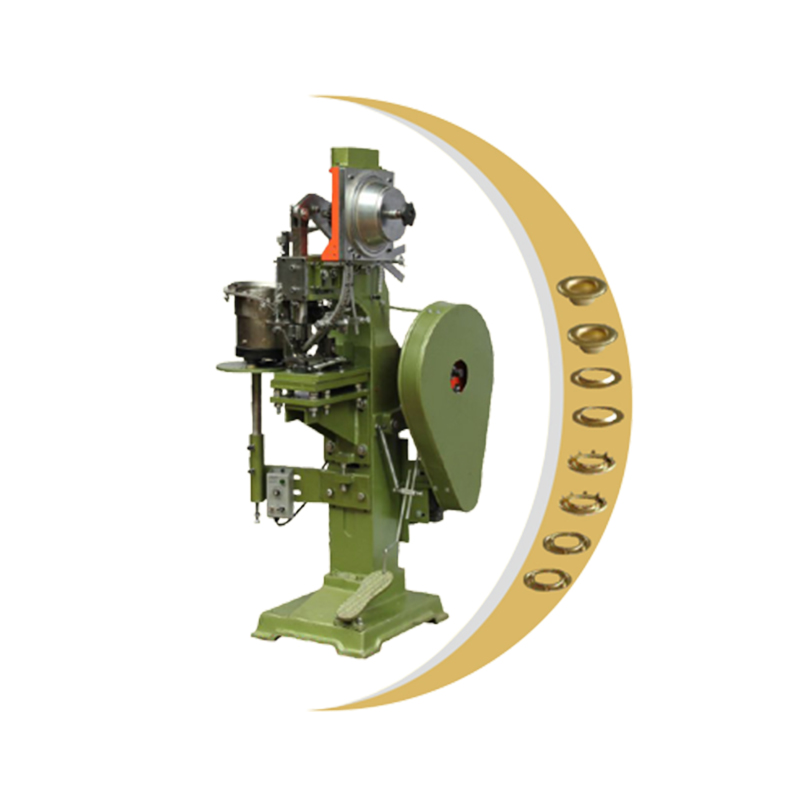

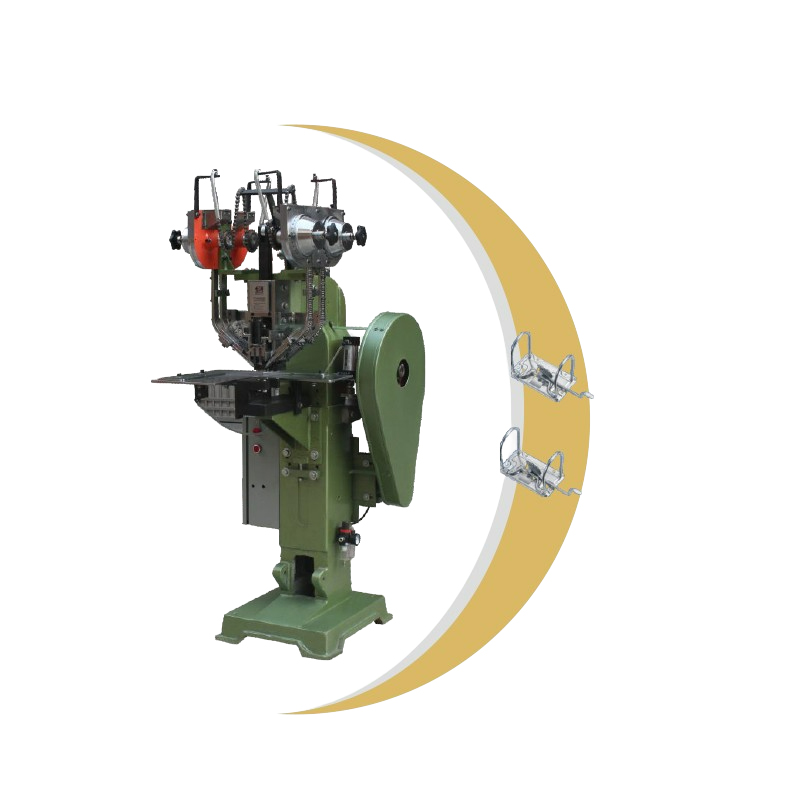

Manufactur standard Foot Operated Rivet Fixing Machine - Four Riveting Machine for Lever arch file / File folder JZ-936SH-4 – Jiuzhou

Manufactur standard Foot Operated Rivet Fixing Machine - Four Riveting Machine for Lever arch file / File folder JZ-936SH-4 – Jiuzhou Detail:

Application

Specially used for fixing four eyelets / hollow rivets on lever arch file, file folder briefcases, clipboards etc.

Feature

1. For riveting of four eyelets or hollow rivets on lever arch mechanism or slide-in plate.

2. The machine simultaneously feeds 4 rivets down from the track and performs riveting at the same time, the force is even, the efficiency is higher and the safety is higher.

3. Driven by a motor and a pulley, the impulse is larger and the riveting effect is better.

4. Machine release is controlled by locating the file properly against with a travel switch and foot switch dual control operation located on the table, this provides maximum safety and reliable for the operator, not easy to cause work injury.

5. Fully customized according to customer folder size and riveting position.

6. Applicable different sizes of file folder, A4 folders or FC folders.

7. Machine can rivet 4 rivets & punching 4 holes at the same operation, holes pre-punched is not necessary.

8. Different voltage applicable to different countries, different regions: 220V single phase,380v three phase,110v single phase…et, Voltage can accept special customized.

9. The machine structure is simple, the debugging is convenient, and the failure is not easy to occur. more flexible and convenient operation.

10. Fixed spindle distance. standard fixed spacing. Customer’s spindle spacing is available.

11. The unique S-seat design of the machine completely fits the lever arch mechanism or the slide-in plate, which is more convenient to operate.

12. High production efficiency with riveting of 9600 pcs per hour.

13. Clamping by high performance material and punch, riveting sample effect is neat, firm, beautiful and not deformed.

14. The spacing of the four riveting position is precise, and the riveting position is not prone to deviation.

Application

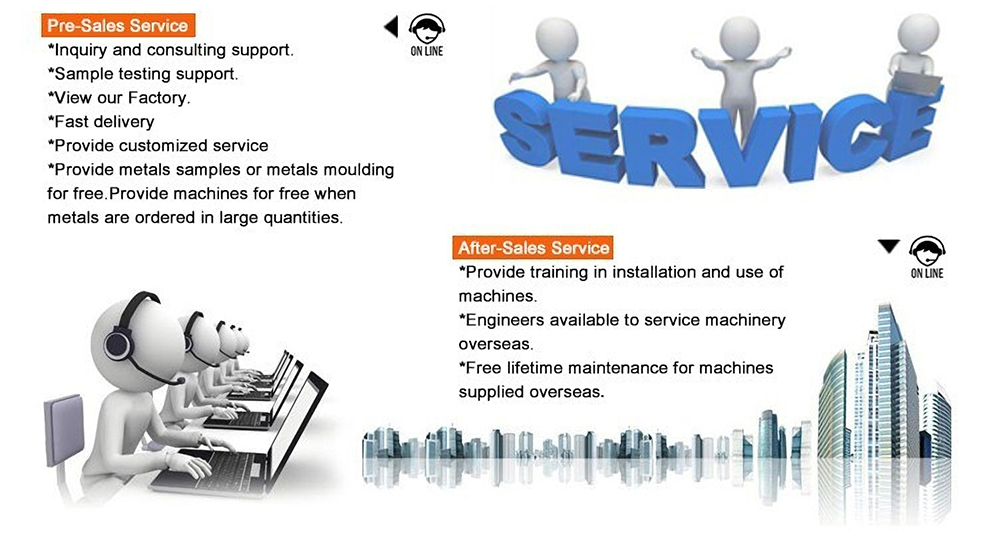

Our Service

Product detail pictures:

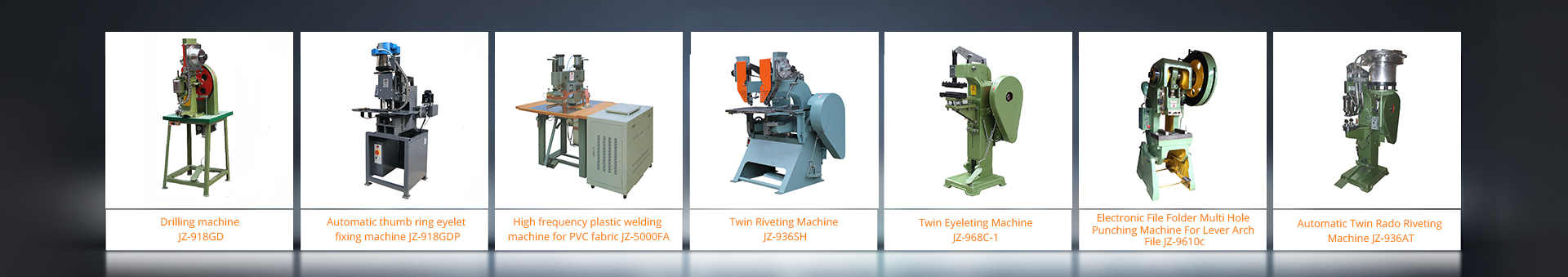

Related Product Guide:

Adhering to the principle of "quality, service, efficiency and growth", we have gained trusts and praises from domestic and international client for Manufactur standard Foot Operated Rivet Fixing Machine - Four Riveting Machine for Lever arch file / File folder JZ-936SH-4 – Jiuzhou , The product will supply to all over the world, such as: Dominica, Brisbane, San Francisco, Our company, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by iso9000 quality management standard strictly , creating top-ranking company by spirit of progress-marking honesty and optimism.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!