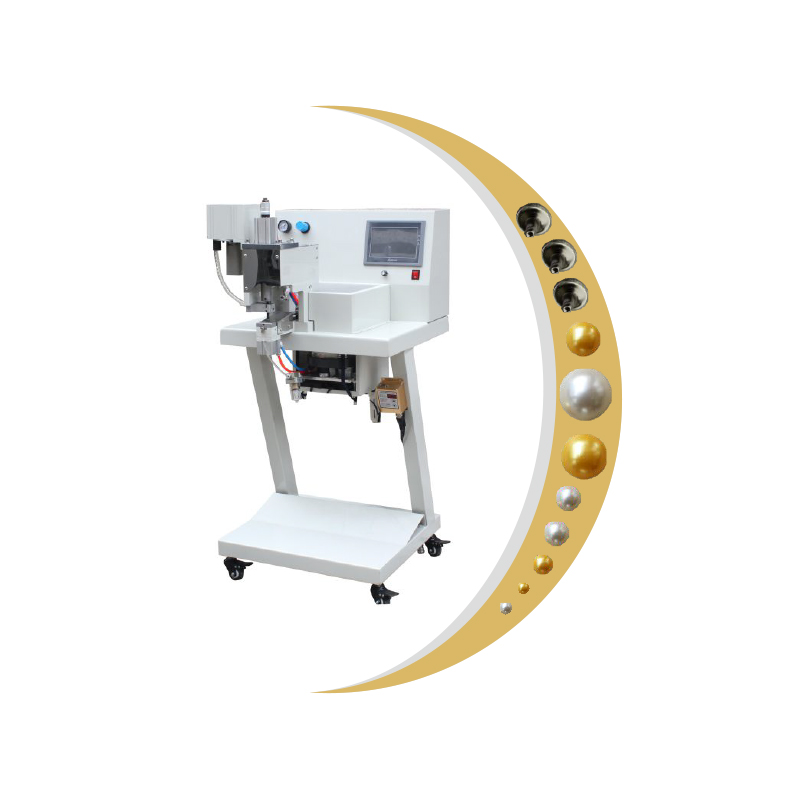

Twin Riveting Machine JZ-936SH – Jiuzhou

Twin Riveting Machine JZ-936SH – Jiuzhou Detail:

| Model | JZ-936SH |

| Rivet head diameter | cD6-12mm |

| Rivet diameter | O2.5-4.5mm |

| Rivet length | 5-18mm |

| Head central distance | 35 (updated)-365mm |

| Throat depth | 440mm |

| Power | 3/4HP |

| Height from floor to bottom mold 850mm | |

| Machine sized*W*H) | 1030×1140 x1420mm3 |

| Net weight | 430kg |

| Gross weight | 565kg |

Application

Feature

Two spindle riveting at one action; Adjustable distance between two rivets (35-365mm).

1.Distance between both heads can be adjusted. Adjustable distance between two eyelets / rivets (35-365mm);

2.Two spindle riveting at one action. Both heads are bound at the time which can improve working efficiency;

3.The machine can automatically punch or continuously punch and fix eyelets;

4.The punching and eyeleting can finish once;

5.The riveted eyelet are neat, beautiful and ametabolic;

6.Easy operation and reliable performance;

7.The efficiency is 8-15 times of manual operation.

8. Adopt a turntable for dividing materials. Rail conveying automatic feeding;

10.The body is made of cast iron. Low noise and good shock-absorbing ability. The function is simple for workers to adjust and use;

9. It is 2-hole riveting at a time. It makes high working efficiency and save working time during a cycle. Moreover, the size and shape of bottom rivet holder can be customized;

10.Top and bottom pieces of the die sets made using optimum mold steel features high durability;

11.Mechanical clutch ensures high operational stability;

12.Lower base can be custom made to adapt to workpieces with different shapes of ring mechanisms or lever arch mechanism.

Specification

Model: JZ-936SH

Rivet head diameter:6-12mm

Rivet diameter:2.5-4.5mm

Rivet length:5-18mm

Head central distance: 35(updated)-365mm

Throat depth:440mm

Power: 3/4HP

Height from floor to bottom mold: 850mm

Machine size: 1030*1140*1420mm3

Net weight/ Gross weight: 430KG / 565KG

Our Service

Product detail pictures:

Related Product Guide:

We always stick to the principle "Quality First, Prestige Supreme". We are fully committed to providing our clients with competitively priced quality products, prompt delivery and professional service for Twin Riveting Machine JZ-936SH – Jiuzhou , The product will supply to all over the world, such as: Macedonia, Swansea, Buenos Aires, Taking the core concept of "to be the Responsible". We'll redound up on society for high quality merchandise and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!